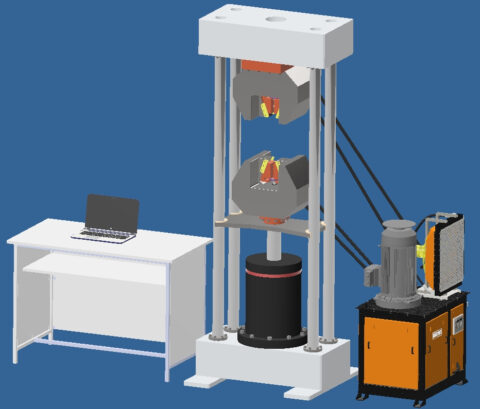

:We supply Tensile, Bending, Flexural, Shear, …. testing machines for different type of metals according to below standards

ASTM A105, A182, A193, A305 Universal ( Tensile, Bending, Flexural) Testing Machine

ASTM A105 / A105M – 21 – Standard Specification for Carbon Steel Forgings for Piping Applications

This specification covers standards for forged carbon steel piping components, that is, flanges, fittings, valves, and similar parts, for use in pressure systems at ambient and higher-temperature service conditions. Materials shall be subjected to heat treatment (annealing, normalizing, tempering, or quenching). Material shall conform to carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum and vanadium contents. The forgings shall be subjected to tension, hardness and hydrostatic tests, with the latter applicable when required. Material shall adhere to tensile strength, yield strength, elongation, reduction of area, and hardness requirements. Guidelines for retreatment, repair by welding, and product marking are given.

This specification covers forged carbon steel piping components for ambient- and higher-temperature service in pressure systems. Included are flanges, fittings, valves, and similar parts ordered either to dimensions specified by the purchaser or to dimensional standards such as the MSS, ASME, and API specifications referenced in Section 2. Forgings made to this specification are limited to a maximum weight of 10 000 lb [4540 kg]. Larger forgings may be ordered to Specification A266/A266M. Tubesheets and hollow cylindrical forgings for pressure vessel shells are not included within the scope of this specification. Although this specification covers some piping components machined from rolled bar and seamless tubular products (see 5.2), it does not cover raw material produced in these product forms.

Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

Specification A266/A266M covers other steel forgings and Specifications A675/A675M and A696 cover other steel bars.

A266/A266M Specification for Carbon Steel Forgings for Pressure Vessel Components

A675/A675M Specification for Steel Bars, Carbon, Hot-Wrought, Special Quality, Mechanical Properties

A696 Specification for Steel Bars, Carbon, Hot-Wrought or Cold-Finished, Special Quality, for Pressure Piping Components

A788/A788M Specification for Steel Forgings, General Requirements

A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A336/A336M Specification for Alloy Steel Forgings for Pressure and High-Temperature Parts

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

A479/A479M Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A511/A511M Specification for Seamless Stainless Steel Mechanical Tubing and Hollow Bar

A739 Specification for Steel Bars, Alloy, Hot-Wrought, for Elevated Temperature or Pressure-Containing Parts, or Both

A763 Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

A788/A788M Specification for Steel Forgings, General Requirements

A923 Test Methods for Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless Steels

A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

A965/A965M Specification for Steel Forgings, Austenitic, for Pressure and High Temperature Parts

A1049/A1049M Specification for Stainless Steel Forgings, Ferritic/Austenitic (Duplex), for Pressure Vessels and Related Components

A1084 Test Method for Detecting Detrimental Phases in Lean Duplex Austenitic/Ferritic Stainless Steels

E92 Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

Keywords

Boilers And Pressure Vessels – Carbon Steel – Flanges – Forgings – High-Temperature Service Applications – High-Temperature Services – Pipe Fittings – Pipes And Fittings – Pressure Vessels – Pressure-Containing Parts – Steel Forgings – Steel Pipes – Tubular Products – Valves

Faratest Co supplies testing machines.

Tel: +98 21 88705040

Whatsapp & Telegram: +98 912 1508626